The Land Based Magnetic Range is a magnetically controlled environment fully designed, developed and built by IFEN naval Magnetism Division, which is provided with a three-axis simulator and has the following capabilities:

- measurement of magnetic perturbation (i.e., magnetic signature) created by components and equipments for low magnetic signature projects;

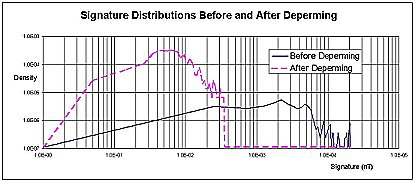

- magnetic normalization treatments (i.e., deperming) on ferromagnetic components to reduce permanent magnetization and bring it into a stable condition;

- susceptibility tests to high intensity magnetic fields (steady and slowly variable) on equipment of even large dimensions.

- design and test of scaled down magnetic models for projects development and validations.

Thanks to an effective and accurate canceling of undesirable perturbations such as the fluctuations of the simulator fields and the Earth's field, magnetostatic signature measurements guarantee an overall accuracy better than 1% of the peak value or 1 nT (nanoTesla), whichever is greater.

The Range Building is a completely non-magnetic construction where the test sample is carried over a wooden carriage and moved over the measuring probes which are placed inside a trench at the center of the building.

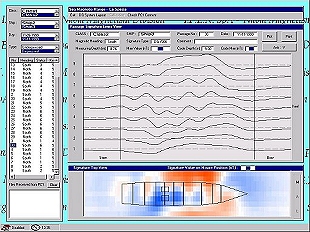

During test sample run the outputs of nine (9) three axis probes are simultaneously sampled and recorded in order to plot the magnetic signature on nine longitudinal equally spaced lines.

Special computer software tools (designed and developed by Naval Magnetism Division) control measurement process and data analysis and presentation.

The Land Based Magnetic Range is provided with various utilities and equipment for deperming normalization treatment on small and quite large items.

IFEN SpA has on this field a certainly unique experience in the world, based on successful treatment of over 200,000 components of all the possible shapes, dimensions and magnetic materials.

These components were principally used in the construction of equipment and system to be installed onboard low magnetic signature vessels.

Deperming equipment, systems, procedures and software tools have been developed by IFEN that holds the property and exclusive use of them.

They constitute a really unique know-how, as it is demonstrated by final permanent magnetization values and time stability.

Specifically onboard steel hulled naval vessels and when the operating environment foresees the presence of high intensity magnetic fields (> 10 Gauss), verification that equipment is not susceptible to steady or low frequency variable magnetic field of such levels is a necessary step of the qualification process. Testing according to DOD-STD-1399 and other standards is a typical service provided by our Range.

Even if IFEN avails itself of internally developed math magnetic modelling tools which have been extensively validated and proven effective, design and development of vessel and equipment magnetic mock up is an available service that can be provided upon specific request of the contractor.

Since scaled-down magnetic model is built starting from samples of the actual ferromagnetic materials used for vessel construction, it indeed provides useful information base for calibrating the degaussing system.

Best compensation in worldwide scenario can be therefore guaranteed even for large vessels whose dimensions make very difficult and expensive magnetic ranging at available facilities.